2024 - Stanford University

A Dramatic Retelling of an Ananse Story

How do we archive culture?

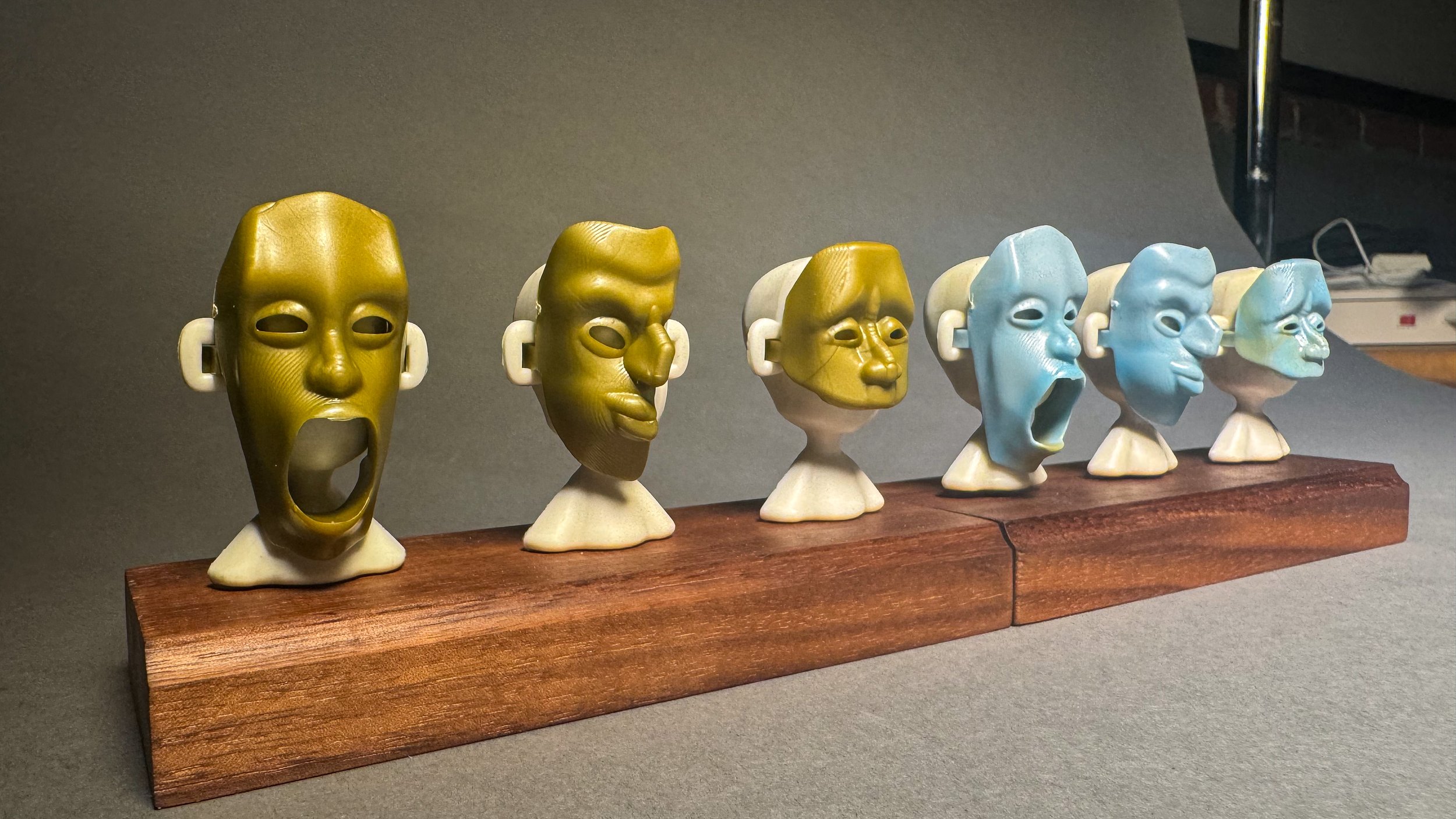

Oral traditions permeated home as my grandmother shared folktales about Ananse the spider with me growing up. This set of injection molded figurines, with masks inspired by Commedia Dell’arte theatre traditions, retells one of these stories. It enshrines the main character’s journey in a cultural artifact.

MATERIALS

polypropylene with stainless steel hardware and poplar base

THE CHALLENGE

Design a part or family of injection molded parts that interact in a geometrically meaningful way with multiple copies of itself or an existing component.

ME325 - Making Multiples: Injection Molding

Budget

Timeframe

$60

5 Weeks

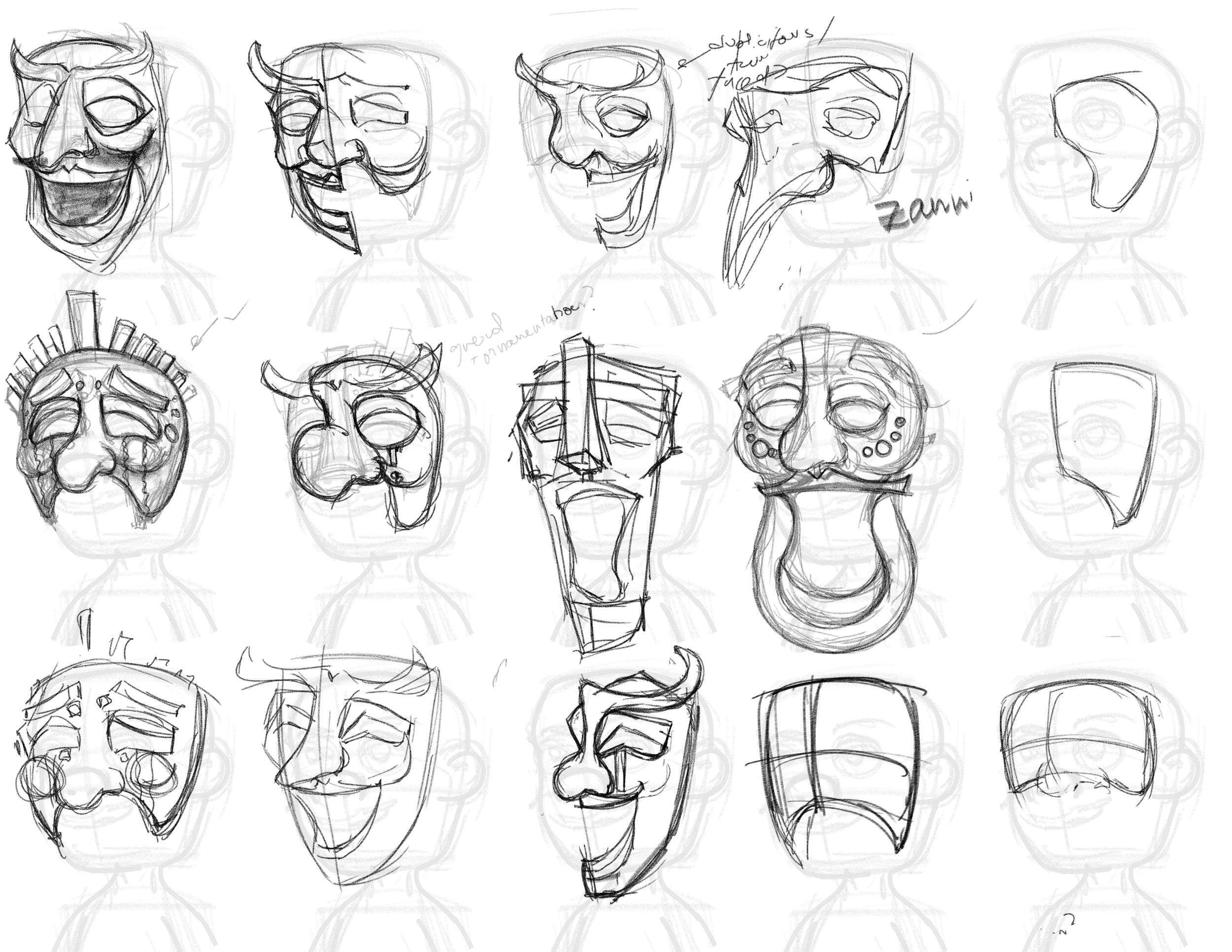

Design: Exploration

Designing Interacting Parts

I started with a character study because I saw an opportunity to explore stylized illustrations in 3D form with the vibrant material color options. In considering stories that were important for me to tell through this study, I began to explore creating a cultural artifact.

The masks’ interchangeability fit the design brief, and introduced a fun interactive element. It would allow the cultural artifact to live and evolve over time with the story.

Mask Design

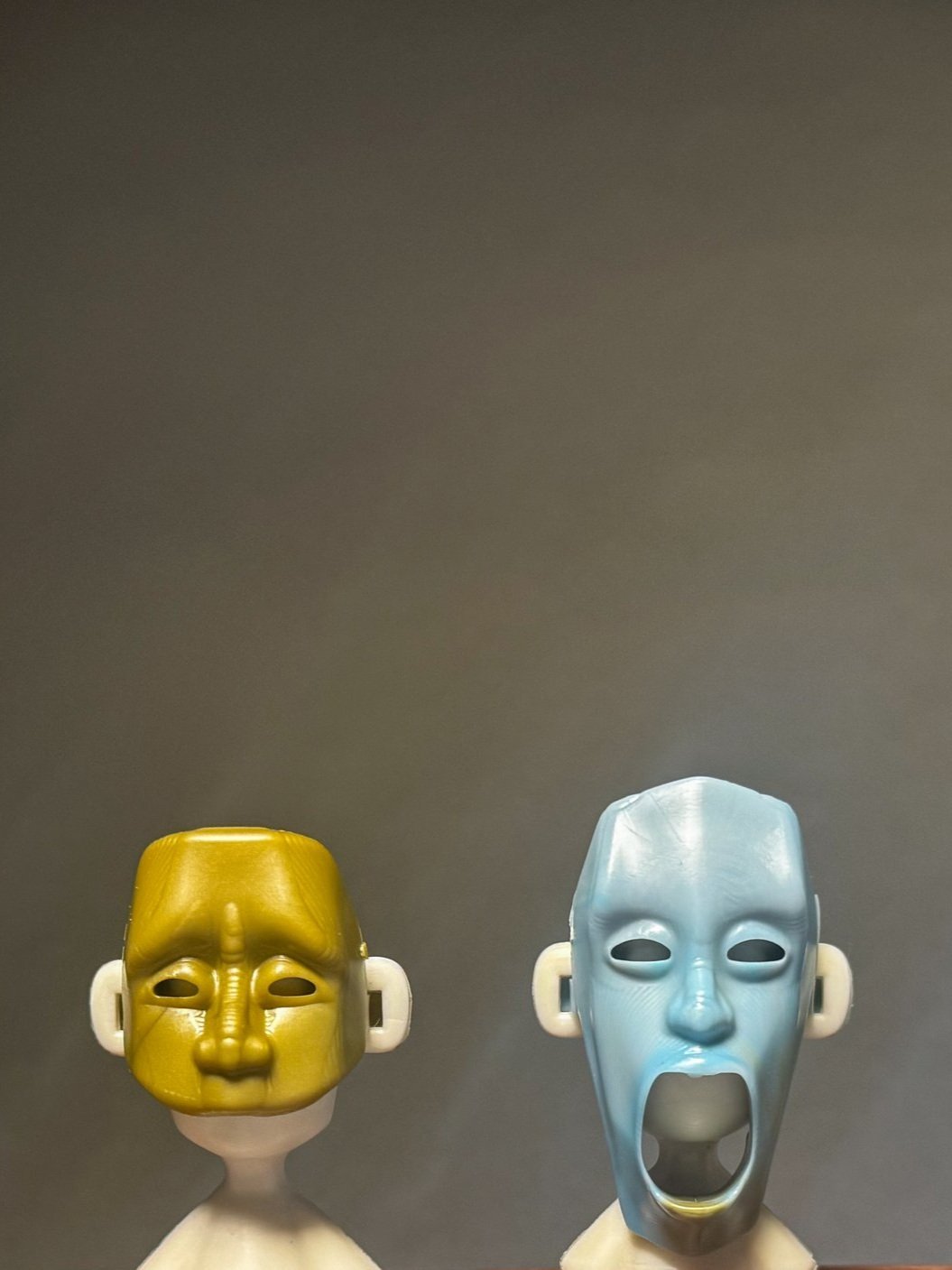

I was inspired by commedia dell’arte stock characters because the archetypes felt very specific yet legible, and I could see the main character, Ananse, performing these various roles through his journey in the story. The commedia masks are also incredibly expressive, particularly in the contortions of the brow, in a way that I felt could enrich the masks as a storytelling medium.

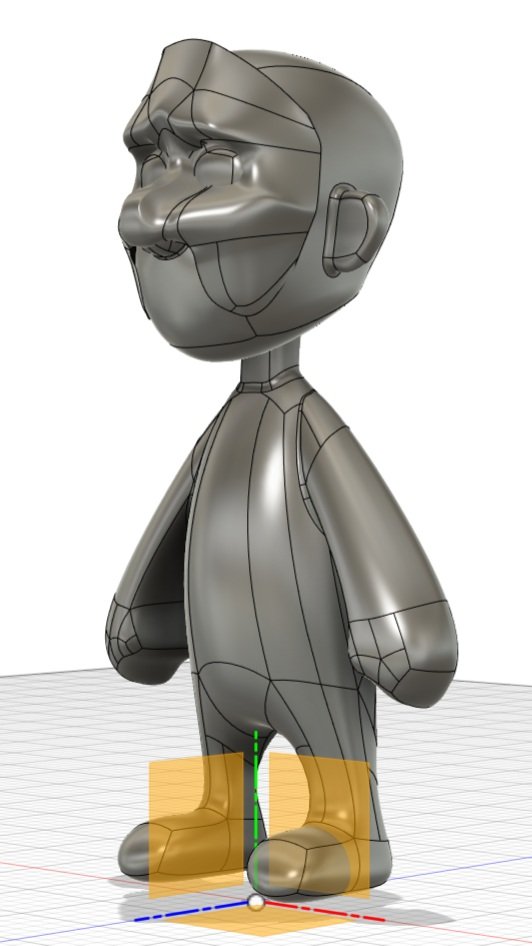

Design: Part Details

Bust face surface as rough guideline

Initial Mask and Bust Formgiving

I cut the figurine off at the chest to reduce the volume of material used, and mitigate anticipated sink issues.

Draft analysis was helpful in adjusting the model to align the change in draft of the ears, head and chest. This allowed me to machine the mold with a consistent parting line.

Tapered arm to reduce strain during snap fit deflection.

Increased radii to dissipate potential stress concentrations.

Small angle for more permanent snap fit joint.

Mask-Bust interface design

Solid body mask through form tool and surface modeling

Details & Refinement: Mask & Joint Design

Refinement through multi-material prototyping

Mask snap fit design considerations

I refined joint dimensions, fit and feel with 3D printed prototypes.

I molded masks and adjusted the interfacing geometry on 3D printed prototypes of the figurine to account for polypropylene shrink.

0.01” gap between mask cut-outs and bust to account for 1%~2% polypropylene shrinkage in mask and avoid assembly interference.

Nose to act as locating feature to ease mask-bust assembly.

Details & Refinement: Bust Design

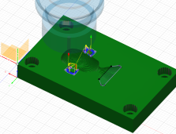

Design: Tooling

Mask Mold

Cavity

Core

Poor initial positioning of masks in mold restricted runner access to injection point. I narrowed the runner on the mold cavity, and added a pocket on the mold core to minimize impact on plastic flow

Gates positioned to inject into cavity at thickest portion of the mask

Parting line shifted to back of mask to minimize flash visibility for better cosmetic finish

1 degree draft angle added to core walls and sliding shutoffs to ease mold assembly and part release

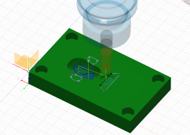

Bust Mold

A-Side

B-Side

Additional radii for mold machinability and ease of part ejection

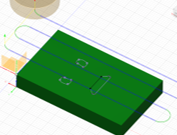

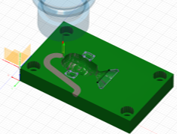

Design: Mold Machine Toolpaths

Facing - 2" Shell Mill

Counterbore Pocket - 1/2" FEM

Bust Clearing Pocket - 1/2" FEM

Bore Pocket - 1/4" FEM

Bust Clearing Pocket - 1/4" FEM

Bust Clearing Pocket - 1/8" FEM

Ears Clearing Pocket - 1/16" FEM

Bust Steep & Shallow - 1/8" BEM

Ears Steep & Shallow - 1/16" FEM

Gate & Runner Trace - 1/4" & 1/16" BEM

Pin Pocket - 1/16" FEM

Pin Steep & Shallow - 1/16" BEM

Fabrication

Uneven cooling led to significant sink in the figurines. Placing them in a water bath helped regulate cooling and eliminate defects.

I over-molded the figurines onto tightly toleranced stainless steel pins which allowed for easier installation into decorative wooden base. I serrated the pins to get a stronger joint.

Design: Future Considerations

Risks

Efficiency

Root Cause(s)

Next Steps

Sink and other cosmetic defects

Manual part removal is difficult and time consuming

Removal process and can damage or break snaps

Making 3 masks for every 1 bust

Uneven mask wall thickness

Solid bust/figurine à uneven cooling challenges

Increase draft angle and radii on snap geometry to stream-line release

Incorporate ejector pins that eject from hidden mask face

Design a family mold for busts that can support a 1:1 production of masks to busts.

Re-design masks to have even thickness throughout and flatten out regions on figurine that might interfere

Core out bust: split figurine into two halves that can be ultrasonically welded together, OR cut the bust in half behind the ear and hollow it out, adding ribs where necessary

Ananse and the Gum Body Statue

as told by masks

Greed

Ananse covets the food on his family’s farm and wants it all for himself

Deceit

Ananse hatches a con to get the object of his desire

Shame

Ananse’s con is uncovered and he is shamed by his village